Finland’s concrete stock binds approximately 3.8 million tons of carbon dioxide

Finland’s concrete stock binds approximately 3.8 million tons of carbon dioxide

CO₂ncrete Solution is a sub-project for the CANEMURE project that investigates the carbon absorption of concrete in Finland and aims for new recycling methods in which the carbonation of concrete could be utilized. As part of the project, Finland’s existing concrete stock has now been analyzed and bound carbon dioxide has been calculated.

The binding agent of concrete, cement, reacts with atmospheric carbon dioxide in a reaction called carbonation. The cement basically turns back into its original form, limestone, binding the carbon permanently. This reaction occurs in buildings during their service life; when the building is demolished and the concrete crushed, a significant amount of non-carbonated surface area is exposed, and carbon sequestration is greatly enhanced.

In the first phase of the project, existing research on concrete carbon sequestration was mapped and the methods of calculation were studied. This provided a strong basis for further research. The results of the studies vary greatly, depending on the time span, location and structure studied, but it was evident that concrete forms a large carbon sink and a permanent carbon storage. The recycling phase was identified to have a great impact on carbon sequestration of concrete, but related studies were somewhat light. (link to literature study)

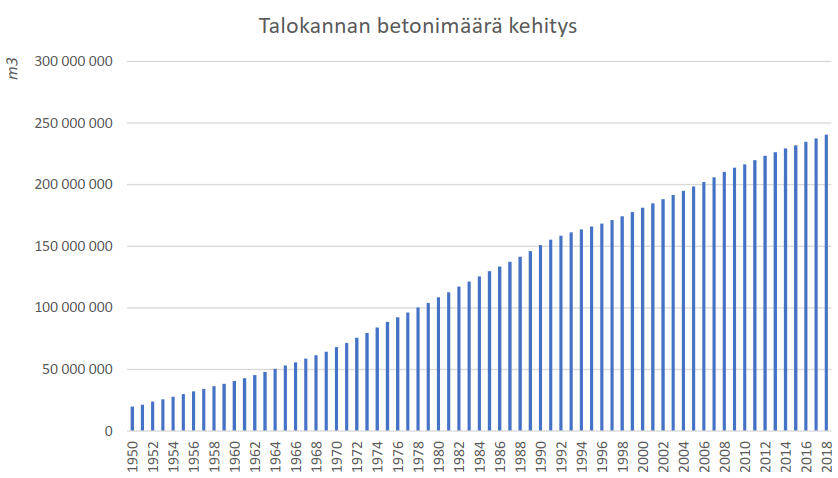

As Finland has accurate statistics on the built environment the analysis of Finnish concrete stock was decided to do as exactly as possible to obtain the highest possible quality of the base data for the calculation. Forecon Oy has a long experience on analysis of the built environment and was chosen as a partner for the task. Finland’s building and infrastructure stock was modelled according to the different structural elements of different building types, characteristic of each decade. This, in turn, was compared with cement sales statistics in Finland. The correlation of the modeling turned out to be excellent and the results obtained can be considered very accurate. According to the analysis, Finland’s concrete stock in 2018 was approximately 340 million cubic meters (m³) of concrete, of which 241 million cubic metres are in the building stock and 98 million cubic metres in infrastructure. Below is presented a graph of the development of the amount of concrete in the building stock since 1950; the graph takes into account the removal of concrete.

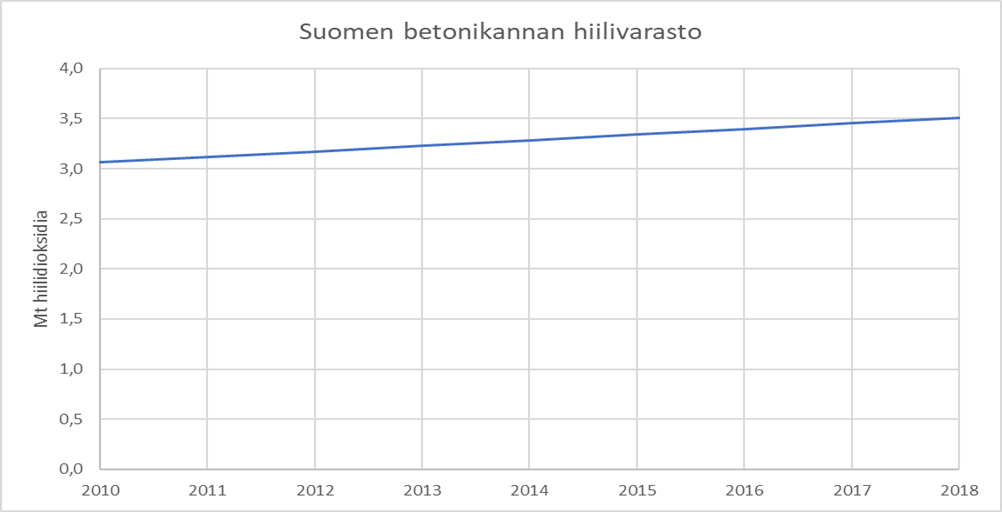

In the analysis, concrete surfaces were divided into groups relevant to carbonation based on the exposure conditions, which made it possible to calculate the depth of the carbonation front in different cases based on the year of construction. Based on these, the total volume of carbonated concrete was obtained. Concrete surfaces that are not in contact with air were assumed to be non-carbonated in this case, although the reaction does occur even under such conditions. Based on the literature study, the amount of carbon dioxide absorbed into concrete could be calculated from this volume.

By 2018, Finland’s concrete stock had sequestered 3.8 million tonnes of carbon dioxide. Of this, 3.5 million tons has been bound to buildings. The carbon stock has grown quite steadily, and the annual carbon sink of concrete is approx. 60 kt (CO₂), which corresponds to about 7 % of the total emissions of Finnish cement production. These calculations do not take into account the effect of crushed recycled concrete.

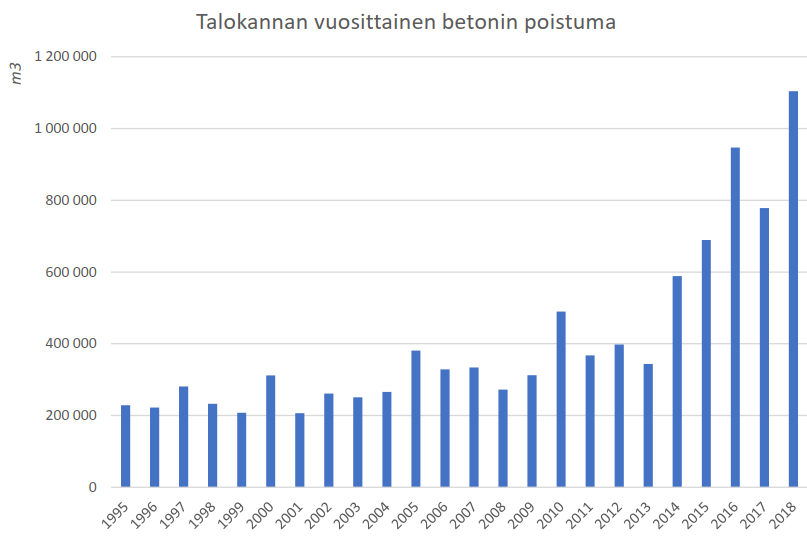

The analysis also modelled disassembled concrete structures, the amount of which has been rising in recent years as new construction has replaced old. In 2018, approximately 1.1 million cubic meters of concrete was disassembled; The annual amount of concrete disassembly is illustrated in the diagram below. In the recycling phase, a great amount of fresh surface area is exposed, and particle size is significantly reduced. This causes a significant increase in carbon sequestration. The continuation of the project will focus on studying this phase, how recycling methods could be used as well as possible utilises concrete as a carbon sink and permanent carbon storage and at the same time save on the extraction of virgin aggregate.